This piece has been made in association with BMC.

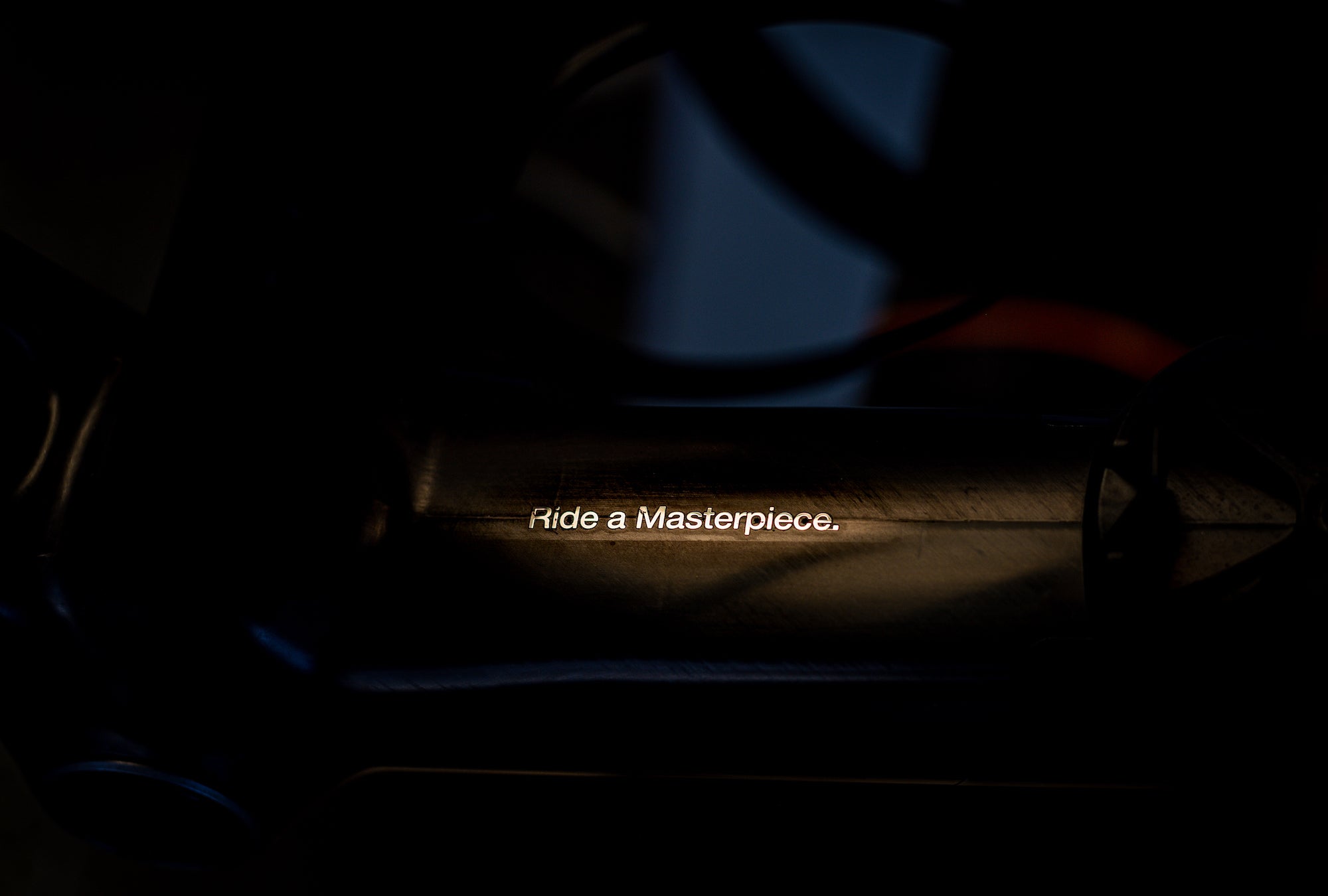

It is safe to say that few bicycle manufacturers could name one of their bikes a ‘masterpiece’ without appearing pretentious. But BMC is one of the rare exceptions.

After all, the Swiss company has been building bikes for the greatest talents in the peloton for years. From Tour de France champion Cadel Evans, through Olympic gold medallists like Greg Van Avermaet to world champions like Philippe Gilbert and Pauline Ferrand-Prévot, BMC has honed carbon fibre frame building to the summit of the sport. So when they actually qualify a new model as a Masterpiece, it is worth taking note.

But what is the BMC Masterpiece?

“The Masterpiece really came from our ambition to one day have a product that came out of the mould already as a finished product,” says Stefan Christ, head of research and development at BMC. A composite engineer, Christ was long fascinated by the idea of producing a one-piece carbon frame, as strong and stable as their time-tested road bikes, but one even sleeker and lighter. The result is the Masterpiece, a hand-made frame produced by one craftsman from start to finish, meticulously applying each layer of carbon so that it lines up perfectly. There is no unnecessary overlapping, which can appear sloppy and adds weight. And the results are stunning.

A composite engineer, Christ was long fascinated by the idea of producing a one-piece carbon frame, as strong and stable as their time-tested road bikes, but one even sleeker and lighter. The result is the Masterpiece, a hand-made frame produced by one craftsman from start to finish, meticulously applying each layer of carbon so that it lines up perfectly. There is no unnecessary overlapping, which can appear sloppy and adds weight. And the results are stunning.

“I have been at BMC for 15 years. And when I first joined the team, my first challenge was to fix quality control issues with the Pro Machine,” explains Christ. “It was a great bike but we were having problems with it cracking. It was made of nine parts bonded together, and we soon realised the bonding points were sensitive and we were over-sanding these sections to make the surface smooth. It was a human operation and simply not well controlled.” But the challenges, while frustrating at first, proved to be a real watershed for Christ as well as his entire team at BMC. “That was a huge turning point for us, and we started making frames with fewer pieces, with less bonding, which reduced our risks. And in a way that was the starting point for the Masterpiece, which is essentially a one-piece frame straight out of the mould. It is the result of years and years of work, years of evolution.”

But the challenges, while frustrating at first, proved to be a real watershed for Christ as well as his entire team at BMC. “That was a huge turning point for us, and we started making frames with fewer pieces, with less bonding, which reduced our risks. And in a way that was the starting point for the Masterpiece, which is essentially a one-piece frame straight out of the mould. It is the result of years and years of work, years of evolution.”

Christ explains the genesis of the Masterpiece from deep within the Impec Lab at BMC’s home in Grenchen, Switzerland. Few people, even within the company, have access to the lab, as this is where the company’s biggest secrets are held. But it is here where their biggest dreams are born as well.  It is clear when talking with Christ that the realisation of the Masterpiece has been nothing short of a labour of love. Eyeing one of Cadel Evans’ original Pro Machines, he then looks to a freshly-produced Masterpiece. No words are needed. The satisfaction is self-evident.

It is clear when talking with Christ that the realisation of the Masterpiece has been nothing short of a labour of love. Eyeing one of Cadel Evans’ original Pro Machines, he then looks to a freshly-produced Masterpiece. No words are needed. The satisfaction is self-evident.

“Before, there were parts of the carbon that were a bit free-form and you could see the different layers of carbon,” explains Christ. “But with the Masterpiece it is very smooth right out of the mould. Essentially you take it out, you clean the moulding lines and that is your bike. But to do that, the quality had to be superlative. It had to be such that the carbon looked beautiful out of the mould. We really had to be very, very accurate. Every fibre has to be perfectly placed.

"We work very closely with a supplier in Germany who understands this need for perfection and takes nearly three times longer on a Masterpiece than any other traditional manufacturer would on a frame. And that is just to make sure that the bike is perfect out of the mould, that virtually every thread of carbon lines up and that the moulding lines are clean. If a little piece of carbon gets into the moulding line it can compromise the whole bike. I cannot stress enough how much additional time is spent on each Masterpiece.”

But while the Masterpiece embodies perfection, one can also feel the craftsman’s touch. The moulding lines that run through the centre or on the rear triangle, for example, are each a little different. This is a handcrafted product.

In another corner of the factory, Nicola Widmer, one of BMC’s master mechanics, puts the final touches on another Masterpiece special order. “I’ve been working at BMC for three years,” says Widmer, who completed Switzerland’s rigorous three-year bike mechanic programme. “I work on all the bikes here: road, mountain, lifestyle bikes... But building up a Masterpiece is really special. You know the frame is hand-made and you are working with your hands on a hand-made frame.

"Each piece is unique. Every bike is a bit different. You see that the carbon structure is always just a little different, the seams are always a little different. Things like that really make the Masterpiece feel unique. It’s just a special thing.” In many ways the sleek matt black Masterpiece incarnates the idea that form follows function. And the fact that the frame is void of paint or elaborate finishing is quite deliberate, as it allows the eye to focus on the pristine carbon craftsmanship while also saving weight. The Masterpiece in fact checks in at a significant 200 grammes lighter than BMC’s pro Teammachine SLR01.

In many ways the sleek matt black Masterpiece incarnates the idea that form follows function. And the fact that the frame is void of paint or elaborate finishing is quite deliberate, as it allows the eye to focus on the pristine carbon craftsmanship while also saving weight. The Masterpiece in fact checks in at a significant 200 grammes lighter than BMC’s pro Teammachine SLR01.

But such decisions also have certain consequences for a pro team sponsor like BMC. “If we capture the yellow jersey someday, there won’t be a yellow version of the Masterpiece coming out the next day,” laughs Christ. “Why spend all this time and effort to save 200 grammes if you are just going to cover it in paint? No, we can make the lettering yellow but that will be it. Certainly that is not ideal for a sponsor looking for visibility, but the Masterpiece is that special.”

While the first Masterpiece was actually their Roadmachine, the new Teammachine is clearly their state-of-the-art model. “Today you cannot find a 700-gramme frame that is this clean, this elegant and has such a good power transfer,” says Christ. “We took the technology of the Teammachine SLR01, which is a very balanced bicycle in terms of stiffness and comfort. The Teammachine is the choice of the pros. But the Masterpiece is 200 grammes lighter. We have come a long way from the Pro Machine and the Teammachine is already a very, very high-quality product off the line. But to get to the Masterpiece was another big step again. Its stiffness-to-weight ratio is simply unmatched.”

Obviously the Masterpiece comes at a cost. And the fact that it takes three times longer to produce is reflected in the price. Even for the professionals on the BMC-sponsored AG2R-Citroën team, the Masterpiece remains very much an exclusive frame, and only a few riders have received one so far. Ben O’Connor was the first recipient after finishing fourth in the 2021 Tour de France. And Bob Jungels was awarded one after his impressive solo stage win in this year’s Tour. Clearly riders have to merit the Masterpiece. But despite the costs, which vary on the build, orders remain high. “A lot of people buying the Teammachine are already those who bought the Roadmachine. And others followed its development and really want the lightest bike at the highest quality. But mostly those who are buying our Masterpiece are real riders, passionate cyclists who ride a lot. Obviously, there is the price. But those who buy the Masterpiece ride a lot and want to stand out when they are riding.”

But despite the costs, which vary on the build, orders remain high. “A lot of people buying the Teammachine are already those who bought the Roadmachine. And others followed its development and really want the lightest bike at the highest quality. But mostly those who are buying our Masterpiece are real riders, passionate cyclists who ride a lot. Obviously, there is the price. But those who buy the Masterpiece ride a lot and want to stand out when they are riding.”

Christ stops for a moment and pauses while looking over at the Masterpiece. Picking it up, he holds it in his arms, he holds it as one would hold a baby. But then, in many ways, the Masterpiece is his baby. And for Christ, as well as the entire BMC team, the Masterpiece is nothing less than a dream come true.