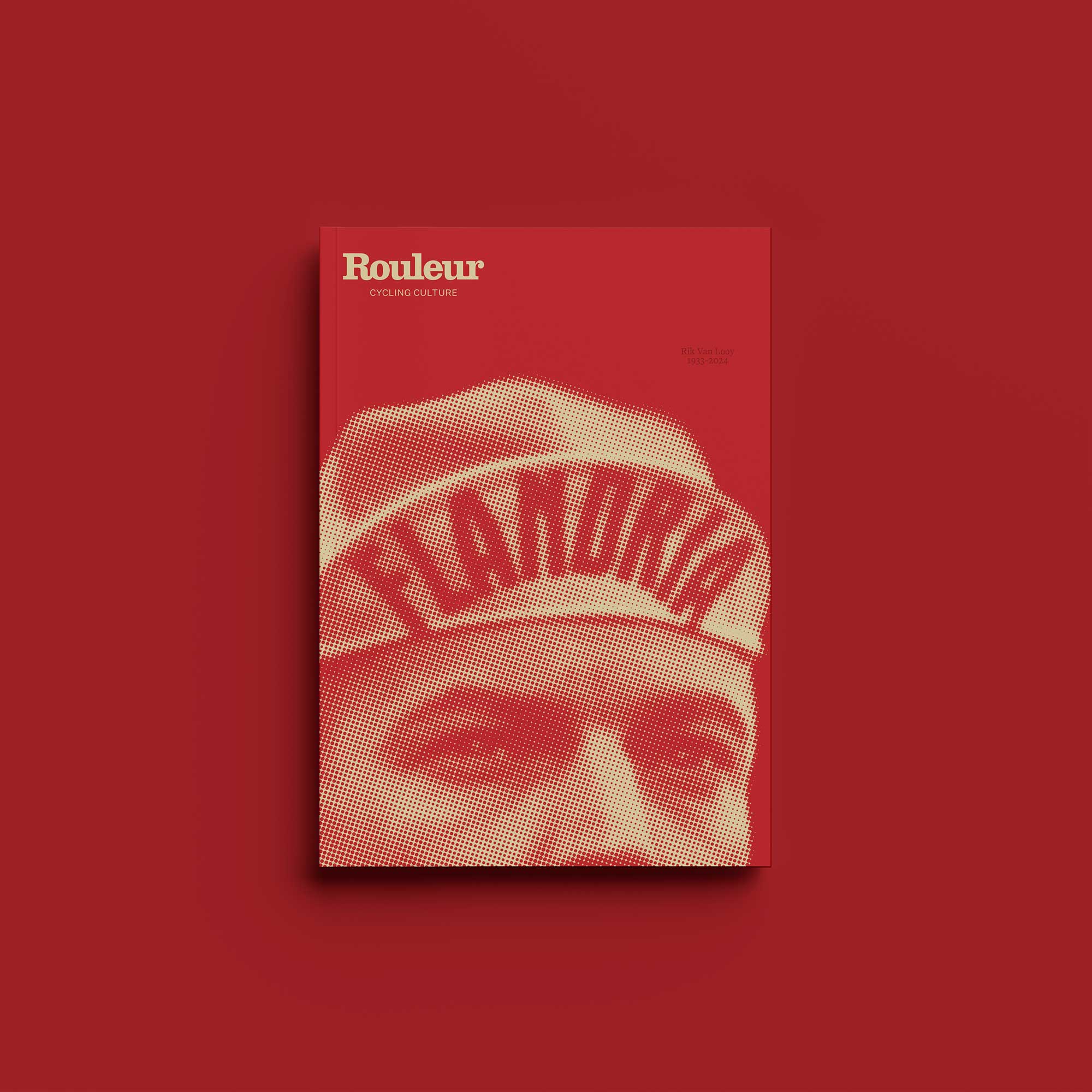

Rouleur: How did the collaboration, with Velobici creating the embroidered cover of our Tour de France special, come about?

Chris: I’ve known [Rouleur Managing Director] Bruce Sandell for a lot of years now. At the last meeting we had he mentioned the idea that Rouleur had for embroidering a jersey and photographing the jersey for the cover. It sounded like a great idea. [Bruce] asked if we could help out there. Obviously with our experience of embroidery that was no problem.

The video of the embroidery is mesmerizing. What was involved in the process?

What happens is, initially you send us the design spec and then we have to create what’s called a “tape”. Once that tape is created it can be altered by 10% in size either way. We then put that onto a disc, create the tape and then do a run-off, to make sure the stitching looks right.

With the look that I felt you wanted to create, it needed to be a Bermalana stitch, which is a heavier gauge, woolen stitch that gives it that retro feel. My idea was, instead of a solid yarn, to use a mélange, which actually has white within it. When you look at the jersey itself, with the embroidery on it, it’s not actually a dark grey or a black thread, it’s a mélange thread, giving it that retro feel that I think looks really cool.

What were the difficulties or challenges with this project?

The main challenge with a Bermalana is to achieve the detail. With, say, the inside point of a capital “A”, if you do the embroidery too small you’re unable to use the stitch, because it gets lost and becomes illegible. We had to make sure the design was big enough to actually be able to use the Bermalana. There was a bit of to-ing and fro-ing, and altering font sizes slightly and things like that. To be honest it was pretty straightforward.

Because you’ve got a lot of experience of doing this sort of thing?

Yeah, and also knowing the brand, and the effect that I thought you would want, it wasn’t too difficult.

There aren’t many brands out there using embroidery, are there?

We tend to use embroidery on most of our garments rather than rubberised badges or print because we think it looks more stylish. It lasts longer. It suits the feel that we want to achieve. People think embroidery is embroidery, but there’s so many different designs of stitches that we can use, like solid stitches and herringbone stitches. You can design within embroidery, not only within the garments themselves.

Can you tell me a bit about your background. How did you come to create Velobici?

I’m a Leicester boy. My parents are both from Leicester. My father was always in knitwear. Leicester has a rich heritage of knitwear, hosiery and garment-making. As a kid I used to be packing jumpers in the old man’s factory.

Ten years ago, because I’ve always had a love for cycling, I just thought it would be great to create a brand that was made in the UK. “Produced in the UK” comes with its own issues, but it works for us because we’ve still got the talent within Leicestershire, that actually produces the quality that we need to produce.

What are those issues?

Cost, mainly, and finding the right factory. We’ve opened our own factory now but it was difficult initially to find a factory to produce the quality that we expect. We used to supply all the components for a jersey – the zips, the fabrics, the grippers – and what they do is cut it, make it and trim it up ready to be packed. Two years ago we opened our own factory unit and produce everything downstairs.

Is that because you were doing well?

We wanted to be reliant on ourselves rather than reliant on other people. What I mean is timescales. If we use a third party you’re governed by outside factors. With the factory downstairs we can develop things a lot quicker. We can design things upstairs and that afternoon we can make a sample and see if it actually does work. 75% of the things that we think could work maybe don’t look right once you put them into production. To have that facility downstairs is very beneficial to what we’re trying to achieve.

Who is the Velobici customer?

The Rouleur reader, basically. Someone who really cares about what they’re wearing when they’re riding their bike. It’s about quality. Everything that leaves the factory is checked and checked and checked again. That’s what we built the business on.

Read: Stillness, speed and reflections – Illustrator Thomas D’Anthony’s take on the Tour

Velobici is, I understand your passion as well as your work?

Chris: Yeah, it’s all-consuming. It’s been my life for ten years and continues to be so. It’s rewarding, frustrating. Put them all in one bag, it does the lot. The business is going from strength to strength. We’re really strong in Asia, probably because of the Made In England thing. There’s a real cycling community over there, especially in Taiwan which is a great market for us. They really love that it’s made here.

Lastly, are you looking forward to the Tour de France?

I have to say the Giro is my favourite race, but the Tour is the biggest race in the world. How can you not look forward to it?

The post Cover stories: How Velobici created the embroidered front page of Rouleur’s Tour de France special appeared first on The world's finest cycling magazine.